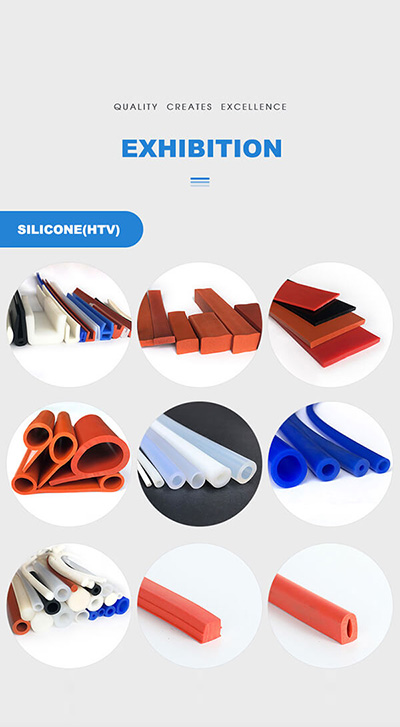

Our Capability and Service

At Tenchy, we pride ourselves on our rapid sample service capability. Our factory is equipped with thousands of extrusion toolings, enabling us to swiftly customize a wide array of silicone tubing and extrusion products for our clients. With over 13 years of experience in the silicone industry, we are dedicated to assisting our customers in finding various solutions, backed by our quick sample service.

Packaging

- Coiled tubing

- Cut to Length and individual PE bag&Label packing

- Customized cartons or bags can be provided in large quantities

- Sample period: 1-2 days(3-5 days for customized tubing)

- Daily production capacity: 10,000 meters

- Transportation: large quantities can be transported by sea, and small quantities can be transported by rail or air

![]()