Thin Wall Silicone Tubing

Tenchy’s thin wall silicone tubing offers unparalleled versatility and customization for various applications. Our advanced extrusion processes allow us to create thin walled rubber tubing with precise specifications, catering to diverse industry needs.

- Customizable Dimensions: Exacting control over inside diameter, outside diameter, and wall thickness (0.1mm+).

- Material Variety: Multi-layer constructions with unique material combinations.

- Precision Engineering: Custom profiles including bends, coils, and pigtails.

- Post-Processing Options: Cutting, spooling, printing, drilling, and more.

- Small Diameter Capabilities: Extrusions under 0.02 inch / 5 mm in diameter.

Thin Wall Silicone Tubing Benefits

Tenchy’s thin wall silicone tubing provides numerous advantages, including excellent flexibility for complex designs, superior chemical resistance for demanding environments, and biocompatibility for medical and food applications. Our custom thin wall rubber sleeve solutions ensure optimal performance and efficiency for your specific needs.

Thin Wall Silicone Rubber Tubing Specifications

| Property | Description |

|---|---|

| Material | Silicone rubber (various grades and durometers available) |

| Inside Diameter | Range of available sizes |

| Outside Diameter | Range of available sizes |

| Wall Thickness | Ultra-thin wall silicone tubing has a starting wall thickness of 0.1mm |

| Length | Custom lengths available |

| Color | Various colors available |

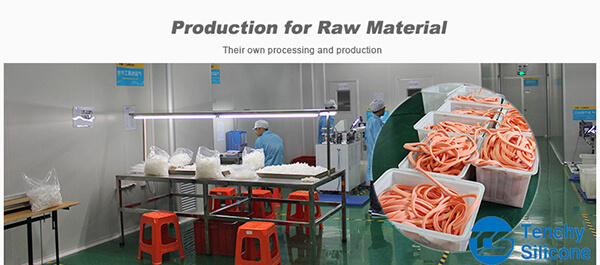

Why Choose Tenchy's Thin Wall Silicone Hose

Discuss your unique thin wall rubber tubing or ultra thin wall rubber tubing needs with Tenchy’s experts and discover the perfect custom solution, including different thin wall rubber tubing sizes. Contact us today!

Thin Walled Silicone Tubing Applications

- Medical Devices: Catheters, feeding tubes, peristaltic pump tubing, respiratory equipment.

- Food & Beverage: Liquid transfer, food handling, beverage dispensing.

- Pharmaceutical: Fluid transfer, chemical processing, research & development.

- Laboratory & Research: Chromatography, fluid handling, analytical equipment.

- Industrial: Pneumatic systems, fluid transfer, peristaltic pumps.

Related News

Exploring the advanced uses of thin wall silicone tubing, this analysis dives into the material’s role within the realm of chemical ecology and how it enables precise fluid management across diverse industries. The contributions of researchers like Mario Kallenbach, who delve into the complex interactions between organisms and chemicals, underscore the relevance of high-quality tubing […]

Thin wall silicone tubing plays a crucial role across diverse industries, from medical and healthcare to food and beverage sectors, owing to its unique properties and versatility. Understanding the meticulous manufacturing process and stringent quality control measures behind its production is essential for ensuring product reliability and regulatory compliance. This article provides a comprehensive overview […]

Choosing the right tubing material is crucial for the success of various applications, ranging from medical devices to industrial systems. Each material offers unique benefits and drawbacks, influencing performance, longevity, and compliance with industry standards. Among these, thin wall silicone tubing is renowned for its flexibility, durability, and biocompatibility, making it a preferred choice in […]

Thin wall silicone tubing is a versatile and widely used component in various industries, from medical devices to food and beverage applications. However, its thin walls can also present unique challenges that require careful handling and maintenance to ensure optimal performance. Understanding the common problems associated with thin wall silicone tubing and implementing effective solutions […]

Thin wall silicone tubing is an essential component in various industries, known for its exceptional flexibility, durability, and resistance to extreme temperatures. Whether you’re working in medical, automotive, or food processing applications, selecting the right thin wall silicone tubing can significantly impact performance and efficiency. Understanding the key factors to consider, such as temperature resistance, […]

In today’s demanding industries, finding reliable, high-performance materials is paramount. When it comes to fluid and gas transfer, few solutions rival the versatility and problem-solving capabilities of thin-wall silicone tubing. This remarkable material, praised for its flexibility, durability, and unique chemical properties, has become an indispensable component across a wide range of sectors. This blog […]