Silicone Foam Seal Basic Information

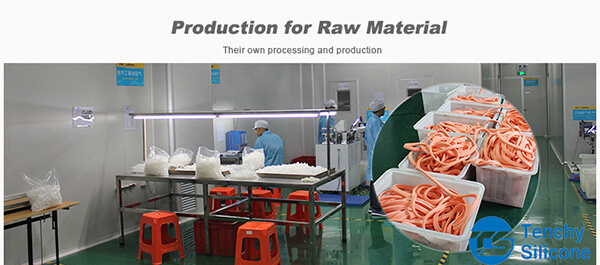

Production process: silicone foam

Material: silicone

Size: customized

Color: black, red, blue, white, gray, green, transparent (other colors can be produced on request)

Non-toxic and tasteless, in line with RoHs Reach requirements

Surface type: smooth or frosted

Sample period: 1-2 days (3-8 days for customized products)

![]()

![]()