Food Grade Silicone Tubing

Food-grade silicone tubing, made from high-elasticity silicone, meets FDA and LFGB standards. Customizable sizes and colors available. Safe for repeated use and sterilization, suitable for food contact.

- High transparency, odorless, tasteless and non-toxic, free of BPA

- High Flexibility, High elastic, resistance to kink and no deformation

- No cracking, long lifespan

- High tearing strength and electrical performance

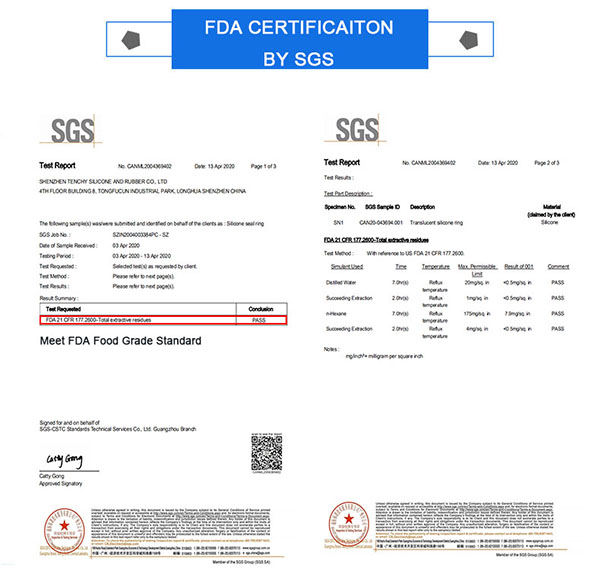

- Meet FDA, RoHS requirements

- No fading or yellowing after long time use or storage

Food Grade Silicone Hose Description

Tenchy, one of the trusted food grade silicone tubing manufacturers, provides food grade silicone tubing, which is made of high elasticity silicone raw material, the silicone tubing meets FDA and LFGB food-grade standards. We can customize food silicone tubes of different sizes and colors for our customers.

Food grade silicone rubber exhibits exceptional resistance to both high and low temperatures. It has good working performance in temperature range -60℃~200°C. And the structure of silicone is extremely stable, resulting in the excellent physical and chemical properties.

The food grade silicone rubber tubing can withstand repeated use and sterilization, and this doesn’t influence its resilience and shape. All food silicone tubes produced by Tenchy are platinum cured, they are odorless, tasteless and non-toxic, suitable for food contact applications.

Food Safe Silicone Tubing Data Sheet

Food Grade Silicone Tubing – General Information

| Feature | Description |

| Product Name | Food Grade Silicone Tubing |

| Certifications | FDA 21 CFR 177.2600, LFGB |

| Material | Silicone |

| Hardness | 50±5 Shore A (Customizable: 30A to 80A) |

| Density | 1.13±0.05 g/cm³ |

| Tensile Strength | >8.5 MPa |

| Elongation at Break | >400% |

| Working Temperature | -60°C to 200°C |

| Compression Set | 8% (150℃/22h) |

| Tear Resistance (Die B) | >25 KN/m |

| Standard Colors | Black, Red, Blue, White, Gray, Green, Transparent (Custom colors available on request) |

| Custom Sizes Available | Yes |

| Wall Thickness | 0.25mm to 20mm |

| Minimum Size | 0.5mm x 1.2mm |

| Minimum Order Quantity | 1000 meters |

| Sample Lead Time | 2-3 days |

| Packaging Options | Coiled, Cut-to-Length with PE bag & label, Custom cartons/bags (bulk orders) |

Food Grade Silicone Tubing – Standard Sizes

| Item # | ID (mm) | OD (mm) | Thickness (mm) | Tolerance (ID) | Tolerance (Thickness) | Available Length per coil (meter) |

| ST-12 | 1.0 | 2.0 | 0.5 | ±0.10 | ±0.05 | 30, 50, 100 |

| ST-1525 | 1.5 | 2.5 | 0.5 | ±0.10 | ±0.05 | 30, 50, 100 |

| ST-23 | 2.0 | 3.0 | 0.5 | ±0.10 | ±0.05 | 30, 50, 100 |

| ST-24 | 2.0 | 4.0 | 1.0 | ±0.10 | ±0.05 | 30, 50, 100 |

| ST-35 | 3.0 | 5.0 | 1.0 | ±0.10 | ±0.10 | 30, 50, 100 |

| ST-47 | 4.0 | 7.0 | 1.5 | ±0.10 | ±0.10 | 30, 50, 100 |

| ST-58 | 5.0 | 8.0 | 1.5 | ±0.15 | ±0.10 | 30, 50, 100 |

| ST-69 | 6.0 | 9.0 | 1.5 | ±0.15 | ±0.10 | 30, 50, 100 |

| ST-710 | 7.0 | 10.0 | 1.5 | ±0.15 | ±0.10 | 30, 50, 100 |

| ST-812 | 8.0 | 12.0 | 2.0 | ±0.20 | ±0.10 | 30, 50, 100 |

| ST-913 | 9.0 | 13.0 | 2.0 | ±0.20 | ±0.10 | 30, 50, 100 |

| ST-1014 | 10.0 | 14.0 | 2.0 | ±0.20 | ±0.10 | 30, 50, 100 |

| ST-1216 | 12.0 | 16.0 | 2.0 | ±0.20 | ±0.10 | 30, 50 |

| ST-1420 | 14.0 | 20.0 | 3.0 | ±0.25 | ±0.15 | 30, 50 |

| ST-1621 | 16.0 | 21.0 | 2.5 | ±0.25 | ±0.15 | 30, 50 |

| ST-1824 | 18.0 | 24.0 | 3.0 | ±0.30 | ±0.15 | 30, 50 |

| ST-2026 | 20.0 | 26.0 | 3.0 | ±0.40 | ±0.20 | 30, 50 |

| ST-2226 | 22.0 | 26.0 | 2.0 | ±0.40 | ±0.20 | 30, 50 |

| ST-2531 | 25.0 | 31.0 | 3.0 | ±0.60 | ±0.20 | 30, 50 |

| ST-3038 | 30.0 | 38.0 | 4.0 | ±0.60 | ±0.30 | 30, 50 |

| ST-3240 | 32.0 | 40.0 | 4.0 | ±0.60 | ±0.40 | 30, 50 |

| ST-3844 | 38.0 | 44.0 | 3.0 | ±0.60 | ±0.40 | 30, 50 |

Why Choose Tenchy's Food Grade Silicone Tubing

Tenchy, among leading silicone rubber tube suppliers, offers swift sample services. Leveraging our extensive array of extrusion toolings, we adeptly customize silicone tubing and extrusion products to meet diverse needs. With over 13 years of industry expertise, we’re committed to delivering tailored solutions promptly.

Applications of Food Grade Silicone Tubes

- Beverage & Dairy handling tubing

- Food processing equipment

- Water purification tubing

- Household appliance

- Brewary&Wine equipment

- Food grade straws

- Sterile Bottle Filling

Related News

When it comes to sourcing silicone tubing manufacturers, the decision holds immense importance for businesses. The quality, cost, and efficiency of the final product are directly influenced by this crucial choice. Ensuring timely delivery of top-notch products is a priority for most companies, with 90% of consumers avoiding businesses with a bad reputation. In today’s competitive landscape, reliability […]

Food-grade silicone tubing is a versatile and essential component in various food processing and handling applications. Renowned for its ability to withstand extreme temperatures, silicone tubing facilitates the transfer of liquids without compromising the quality or safety of the food or beverage it contacts. The durability and resilience of this material make it superior to […]