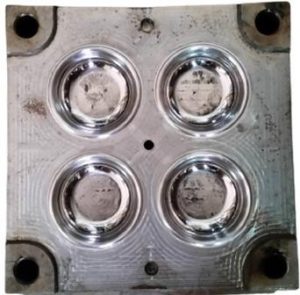

All silicone products must be moulded before production, and new products can be developed through moulds.

The sample mold is also known as the hand mold. When a customer wants us to make a sample, we first need the customer to provide a sample or 2D drawing or 3D drawing. If the customer provides a prototype, we will get a 3D drawing after scanning this prototype. If the customer provides a 3D drawing, it will be more simple. Our mold room master will program and open the mold according to the 3D drawings.

Usually, the sample mold is opened first for the customer to confirm, and then the large mold is opened for production after the customer confirms that there is no problem.

The sample mold usually has 1 to 2 cavities. When there are more samples, our sample mold will also have 4 cavities. Because silicone amterial is flexible, the actual product produced may not be exactly the same as the drawing. At this time, we only have to open a sample mold and print the sample for customers to confirm. If there is a problem with the sample mold, it is relatively simple to modify the mold at this time, the modification time is short, and the efficiency is high. When the product is developed and meets the requirements of the customer, the mold is confirmed at this time.

The raw material of the sample mold

Our company’s sample molds are all made of steel. Decide the size of the template according to the size of the product. Usually, a template with a length * width * height of 300mm*300mm*30mm is used.

Production time of the sample mold

The production time of the sample mold is determined by the complexity of the product structure. It usually takes about 2-3 days from programming to processing for relatively simple products; about 5-7 days for complex products. The more complex the product structure, the longer the mold opening time.

The advantages of opening a sample mold

First of all, the number of holes in the sample mold is small, the use of the template is small, and the processing time is short, so that the cost is relatively small and the efficiency is high.

Secondly, opening the sample mold can also bring some other benefits. For example, even if the product structure is not confirmed for the first time, it is more convenient to modify the mold.

After the modification, the sample can be confirmed immediately, which shortens the time.

Third, because of the low cost, opening the sample mold first can reduce the risk. If you open the big mold directly, you can’t confirm the sample for the first time, and there will be many quality problems when the modified mold is used to produce the product. Therefore, opening a sample mold can achieve the purpose of first confirming the product. If it is confirmed that there is no problem, open the large mold at one time, so that the produced product will rarely have quality problems.