Stainless steel (SS) wire braided silicone hoses offer significant advantages over traditional hoses, particularly when dealing with high-pressure and demanding environments. Their construction provides superior resistance to extreme temperatures, from hot steam to cold refrigerants, ensuring consistent performance across various applications. Moreover, the braiding enhances the structural integrity at connection points, reducing the risk of leaks or hose failure.

Furthermore, the robust composition of these hoses affords them exceptional resistance to extreme pressures and harsh conditions. This makes them ideal for critical applications in industries prioritizing safety and reliability, such as aerospace, automotive, and chemical processing. In this post, we will discuss why SS wire braided silicone hose is an ideal choice for high-pressure applications. Let’s dive in!

BUY SS WIRE BRAIDED SILICONE HOSE HERE

What Are SS Wire Braided Hose Pipes?

![]()

SS wire braided hose pipes are composites of a silicone inner tube reinforced with a braided stainless-steel wire exterior. This combination provides a flexible yet sturdy conduit for fluid and gas transfer under high-pressure conditions. The silicone core can withstand extreme temperatures, making it suitable for a wide range of applications, from heating systems to engine components.

The braided stainless-steel exterior provides protection and reinforces the hose, ensuring it maintains its shape and integrity at critical connection points. This reinforcement allows the hose to handle increased pressure levels without expanding or bursting, which is crucial for safely transporting fluids and gasses.

These hoses are designed for endurance, offering resistance to extreme conditions such as temperature fluctuations, aggressive chemicals, and mechanical stresses. This makes them preferred for applications where reliability and safety are paramount.

BUY SS WIRE BRAIDED SILICONE HOSE HERE

SS Wire Braided Hoses Specifications

SS wire braided hoses are engineered for high-temperature applications and are constructed with high-quality stainless steel that is resistant to corrosion. They offer greater pressure limits than rubber flex connectors, with some rated up to 3000 psi, and are suitable for applications requiring strength and durability.

Their temperature rating exceeds that of rubber connectors, making them ideal for outdoor applications and those involving corrosive chemicals. Combining stainless steel and silicone tubing ensures a longer service life than rubber and the ability to connect with specialty fittings such as raised face or weld neck flanges.

Manufacturing Technique

The manufacturing process of SS wire braided silicone hoses involves a sophisticated technique that integrates multiple layers to achieve optimal performance. The process begins with creating a silicone inner core encased in a braided stainless steel sheath. This braiding is meticulously applied using advanced machinery to ensure uniform coverage and tension, critical for the hose’s pressure-handling capabilities.

Fabric

The fabric used in constructing SS wire braided silicone hoses is a high-grade silicone material chosen for its flexibility and thermal stability. This fabric forms the inner lining of the hose, providing a smooth surface for efficient fluid transfer and acting as a barrier against contaminants. The silicone’s inherent resilience and non-reactive properties make it an excellent choice for various applications.

Steel Wire

The steel wire used in these hoses is selected for its high tensile strength, which provides the structural support needed to withstand the demands of high-pressure applications. The wire is intricately braided around the silicone core, enhancing the hose’s ability to maintain its shape and prevent expansion under pressure, ensuring reliable and consistent performance.

Inner Wall

The inner wall of the SS wire-braided silicone hose has a smooth silicone lining that ensures minimal resistance to fluid flow. This seamless interior allows for the efficient and clean transfer of liquids and gasses, making it ideal for sensitive and high-purity applications where contamination must be avoided.

Outer Wall

The outer wall of the hose consists of a tightly woven layer of stainless steel wires that provide robust protection against physical damage. This layer is crucial in maintaining the hose’s integrity under the strain of high-pressure use and in environments where abrasion or puncture risks are present.

Diameter Range

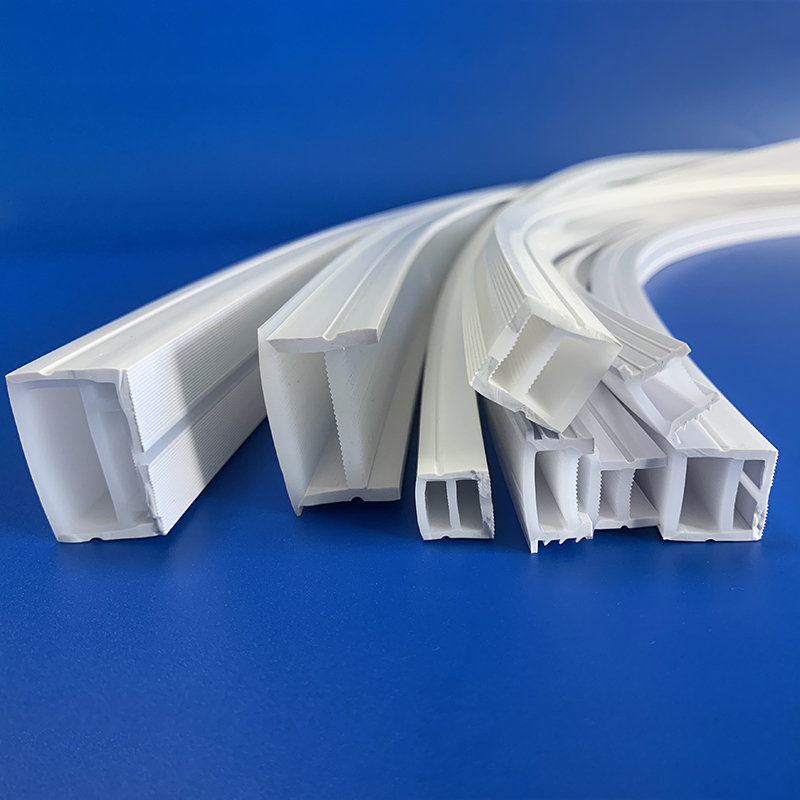

SS wire braided silicone hoses have various diameter ranges to accommodate different fluid transfer requirements. For small-scale laboratory equipment or large industrial machinery, hose size are available to ensure proper flow rates and match each application’s specific needs.

Diameter Tolerance

The diameter tolerance of a hose with braided stainless-steel reinforcement is tightly controlled during manufacturing. This precision ensures a consistent fit and performance across all hoses, facilitating reliable connections and reducing the likelihood of leakage or failure at critical junctions.

Standard Length

Standard lengths of SS wire-braided silicone hoses are manufactured to meet the common requirements of various industries, providing convenient options for installation and replacement. Custom lengths can also be produced to accommodate specific system configurations or to reach remote connection points.

Temperature Range

The SS wire braided silicone hose is designed to operate effectively in a broad temperature range, making it suitable for use in hot and cold environments. This versatility ensures reliable performance across applications that experience significant temperature variations.

Daily Capacity

The daily capacity of manufacturing SS wire braided silicone hoses is a testament to their efficiency in production. Facilities are equipped to handle the pressures of large-scale orders while maintaining stringent quality control, ensuring that each hose meets the high standards required for high-pressure applications.

![]()

BUY SS WIRE BRAIDED SILICONE HOSE HERE

Benefits of SS Wire-Braided Silicone Hose for High-Pressure Applications

SS wire braided silicone hoses excel in performance and reliability in high-pressure applications. Their service life is significantly extended compared to rubber and PVC hoses, reducing the need for frequent replacements. The braided design enables the hose to be bent without compromising its integrity, which is essential in complex hydraulic systems and industrial applications where space is limited. Additionally, the pressure resistance of these hoses is superior, minimizing the risk of physical damage or catastrophic failure, thereby reducing downtime and maintenance.

Higher Pressure Tolerance

SS wire braided silicone hoses are designed to withstand high temperatures and pressures, setting them apart from other hoses. The braided stainless-steel reinforcement provides a robust structure that can handle the rigors of demanding environments where traditional hoses might fail. This high-pressure tolerance is crucial in applications where safety and performance are non-negotiable.

Due to their construction, these hoses maintain their form and function even when exposed to extreme pressures, ensuring a secure and leak-free operation. Their ability to withstand such conditions makes them indispensable in many industrial systems and processes.

Enhanced Longevity and Durability

Integrating 304 stainless steel and 316 stainless steel in steel braided hoses contributes significantly to their longevity. Their woven outer layer offers exceptional corrosion resistance, warding off rust and other corrosive elements that can lead to premature failure. This durability ensures they maintain their integrity for longer than non-braided hoses.

Furthermore, braided stainless-steel reinforcement adds to the robustness of these hoses, making them highly resistant to mechanical damage. Whether exposed to harsh chemicals or physical abrasion, their sturdy construction minimizes wear and tear, ensuring a long service life and reducing the need for frequent replacements.

Increased Flexibility and Ease of Use

SS wire braided silicone hoses are designed to provide superior strength and flexibility, evident in their bend radii. This characteristic allows for greater versatility in hose installation, particularly in tight spaces where rigid hoses would be impractical. The flexibility also minimizes the risk of kinking, which can compromise hose integrity under extreme pressure.

Additionally, the ease of handling and installing these hoses directly benefits their construction. Users experience less strain during installation and can confidently maneuver the hoses into the necessary configuration without sacrificing performance, even in applications involving high-pressure demands.

Temperature and Corrosion Resistance

SS wire braided silicone hoses are engineered to withstand a broad spectrum of temperature extremes, which enhances their applicability in various industrial scenarios. This temperature resistance is paired with an innate ability to resist the detrimental effects of corrosive substances. The combination of these properties ensures that the hose installation can endure harsh environmental conditions without performance degradation.

Another defining feature of these hoses is their ability to adapt to fluctuating pressure levels without compromise. Their construction safeguards against the corrosive effects within the hose, thereby preserving the integrity of the materials and ensuring a consistent and reliable flow of media.

Wide Range of Sizes and Applications

The versatility of SS wire-braided silicone hoses extends to their size variety, accommodating a wide array of diameter requirements for fluid transfer applications. Whether small-diameter hoses are needed for precision instruments or larger ones for industrial machinery, there is a size to fit the specific demands of the application.

Due to their adaptability, these hoses are not limited to a single industry but are employed across multiple sectors. Their broad size range means they can be utilized for tasks as diverse as automotive cooling systems and pharmaceutical manufacturing processes, demonstrating their wide-reaching applicability.

Reliability and Safety

When it comes to high-pressure applications, a hose’s reliability is of paramount importance. SS wire-braided silicone hoses are engineered to withstand burst pressures exceeding typical system demands. This stainless steel construction ensures a high safety margin, significantly reducing the risk of catastrophic failure that can lead to injury or equipment damage.

The consistent performance and robustness of these hoses instill confidence in their use. Thanks to the meticulous design and material selection aimed at providing maximum security and operational reliability, operators can trust in their ability to maintain integrity under rigorous conditions.

Aesthetic Appeal

While functional performance is critical, the aesthetic appeal of SS wire braided silicone hoses should not be underestimated. The gleaming stainless steel construction offers a sleek, professional look that surpasses the often utilitarian appearance of PVC pipes and other hose types. This visual quality can enhance the overall appearance of equipment and installations.

The polished finish of stainless steel adds to the visual appeal and reflects the quality and care put into the construction of these hoses. Their attractive appearance and superior performance make them a preferred choice for applications where aesthetics and functionality are important.

![]()

BUY SS WIRE BRAIDED SILICONE HOSE HERE

Wrap-Up!

SS wire-braided silicone hoses in high-pressure applications are a testament to engineering excellence, blending strength with functionality. They comply with industry standards and often exceed them, offering a reliable choice for many industrial uses. Selecting such hoses ensures a long-term solution that can withstand rigorous conditions without compromising performance.

Whether for the automotive industry, food and beverage processing, or pharmaceutical manufacturing, incorporating SS wire-braided silicone hoses represents a commitment to quality and safety. With their superior design and material composition, these hoses are poised to remain a staple in high-pressure applications, providing peace of mind to operators and engineers alike.